At QANYU, we enhance not just how your parts perform — but how they last and look. Through advanced surface treatment technologies, we improve durability, corrosion resistance, aesthetics, and functionality, helping your products stand out and stay strong.

Surface treatment modifies the outer layer of metal, plastic, or composite materials to strengthen, protect, and beautify them. It’s the final touch that transforms a finished part into a high-performance product — essential across industries like automotive, aerospace, electronics, medical devices, and construction.

Our Core Processes

• Anodizing: Creates a hard, corrosion-resistant oxide layer for aluminum parts.

• Electroplating: Adds protective and decorative metallic coatings.

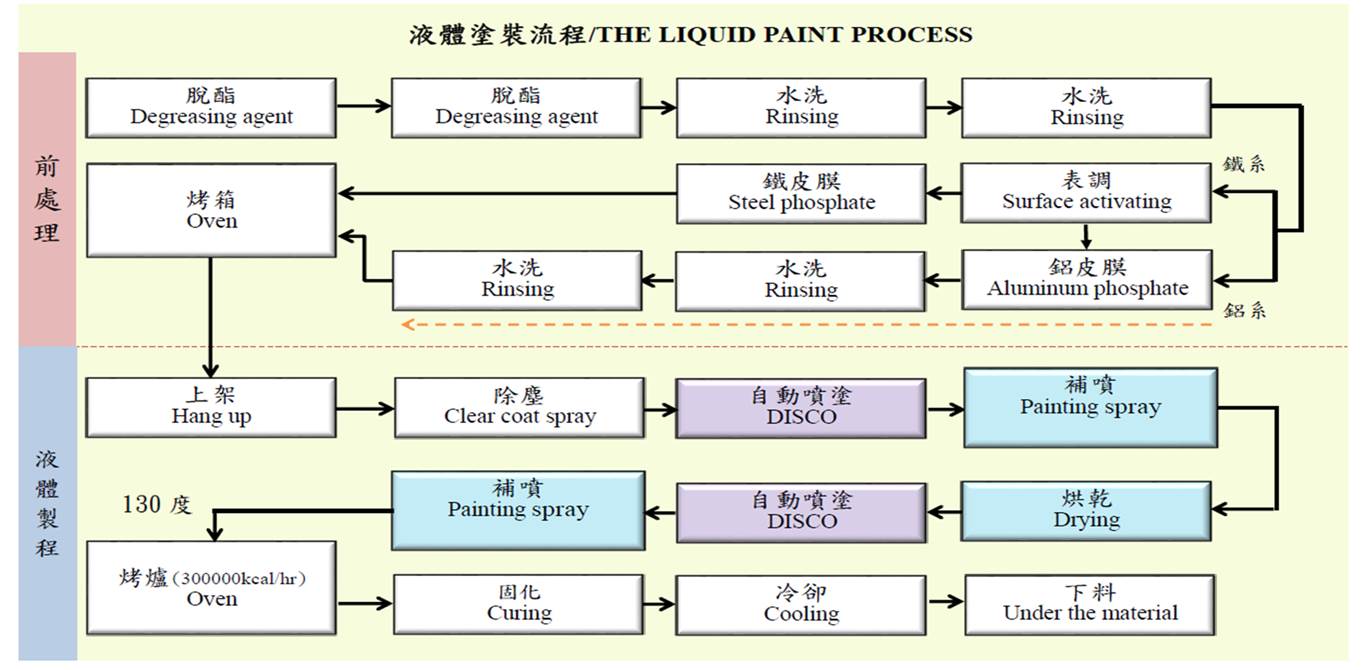

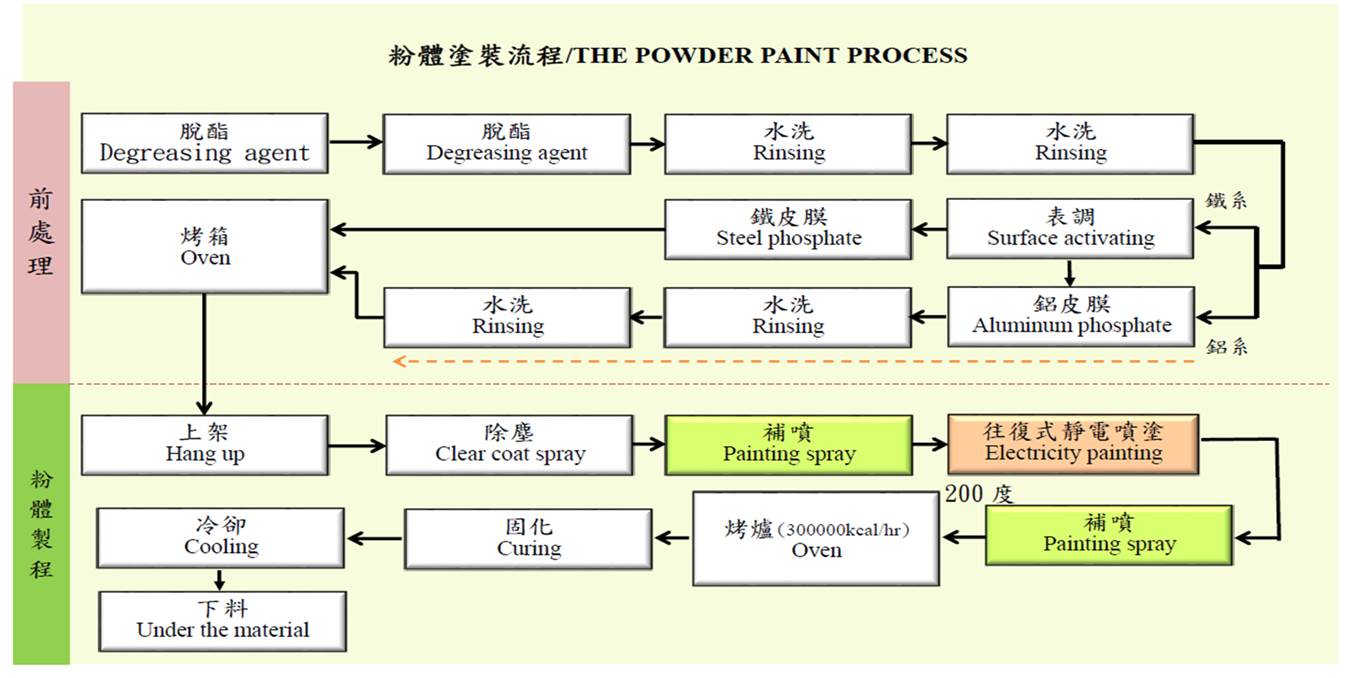

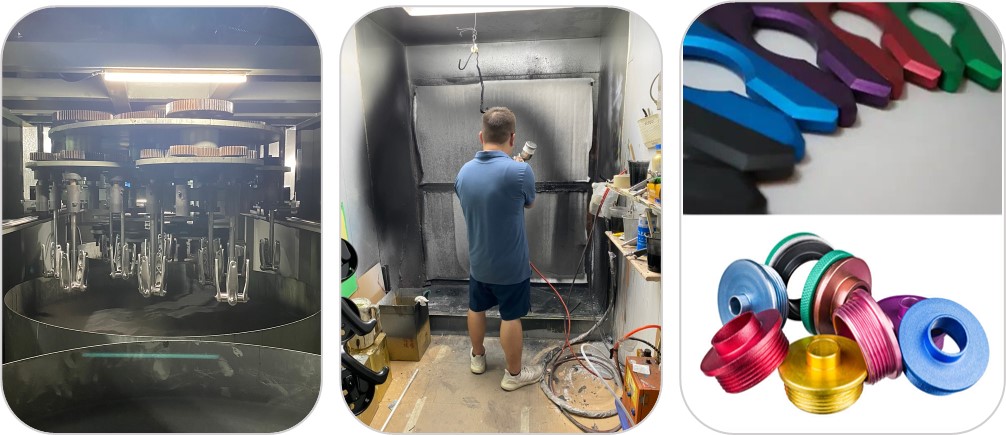

• Powder Coating: Delivers uniform, durable, and colorful finishes.

• Heat Treatment: Enhances hardness, strength, and wear resistance.

• Polishing & Grinding: Achieves smooth, mirror-like surfaces.

• Shot Peening: Improves fatigue resistance by surface compression.

Why Surface Treatment Matters

1. Strength & Protection Corrosion, UV, and wear resistance for long-lasting performance — even in marine or heavy-duty environments.

2. Aesthetic Appeal From matte to mirror finishes, elevate product design and brand perception.

3. Enhanced Functionality Improve hardness, friction control, and thermal resistance for specialized applications.

4. Lower Maintenance Costs Longer part life means fewer replacements and lower total cost of ownership.

5. Tailored Finishes Custom colors, textures, and effects to meet your exact design or performance goals. Our integrated capabilities allow seamless coordination between machining, casting, and surface finishing, ensuring each part meets your mechanical and aesthetic requirements perfectly.