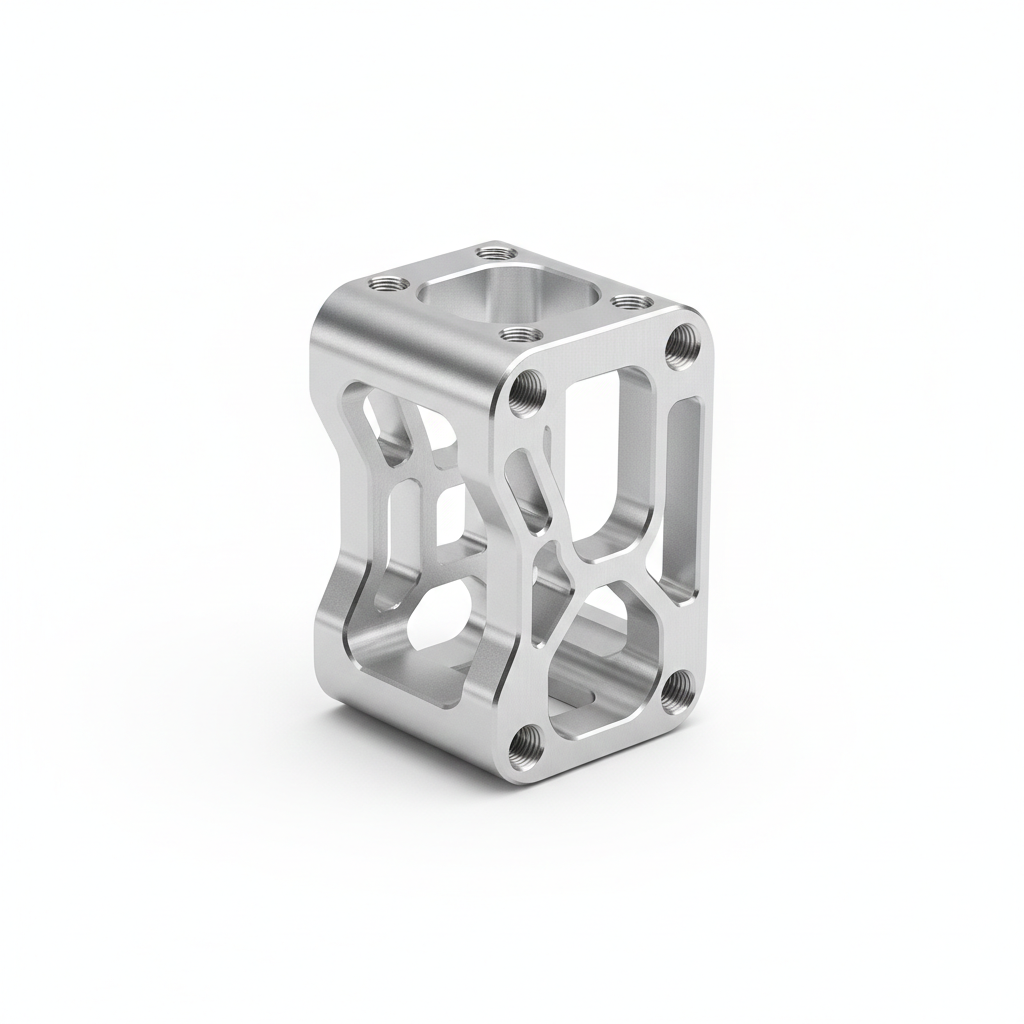

As a professional CNC machining manufacturer, QANYU provides precision machining services for both metal and non-metal components across various industries. Our expertise covers aluminum CNC machining as well as precision processing of materials such as stainless steel, copper, and engineering plastics.

Equipped with advanced 5-axis, turning, and milling technologies, we produce complex parts with exceptional accuracy and consistency. From prototyping to mass production, QANYU delivers reliable, cost-efficient machining solutions tailored to your product needs.

Advanced CNC Capabilities

-

Complex Geometry Manufacturing

5-axis simultaneous machining enables precise multi-angle cutting in a single setup, ideal for complex contours, undercuts, and intricate details.

-

Material Versatility

We machine aluminum, stainless steel, copper, titanium, and engineering plastics, each processed with optimized parameters for consistent quality.

-

High Precision & Tight Tolerances

Dimensional accuracy reaches ±0.005mm, delivering components that meet demanding performance and assembly requirements.

-

Process Stability & Efficiency

Real-time monitoring, precise tool calibration, and digital process control minimize variation and ensure repeatable accuracy across batches.

-

Flexible Production Scale

From rapid prototyping to high-volume manufacturing, our workflow adapts to different requirements while upholding precision and speed.

Quality Control & Inspection Technology

QANYU places strong emphasis on quality assurance, investing in advanced inspection equipment to verify that every part meets international standards and customer specifications. Each component is thoroughly examined for dimensions, surface quality, and material integrity before shipment.

Key testing and measurement systems include:

-

Coordinate Measuring Machine (CMM)

Measures 3D dimensions and geometry with micron-level accuracy to ensure all features match design data.

-

Vision Measuring System (VMS)

Uses optical imaging for non-contact measurement of small or intricate parts.

-

Spectral Analyzer

Confirms the chemical composition of metal alloys to ensure correct material grades.

-

Surface Roughness Tester

Evaluates micro-surface finish to guarantee proper sealing, movement, and appearance.

-

Hardness Tester

Assesses material strength and durability to meet mechanical performance requirements.

Industry Applications

Our precision machining technology supports critical components in:

-

Automotive

Engine parts, transmission components, brake system elements, and EV battery modules.

-

Electronics & Communications

Heat sinks, circuit board brackets, and precision connectors.

-

Medical Devices

Surgical instruments, implant components, and precision housings meeting medical-grade standards.

Why Choose QANYU

-

Integrated Manufacturing Capabilities

We provide one-stop services that extend beyond CNC machining – covering mold design, die casting, forging, and plastic injection molding.

-

Adaptable to Any Production Need

From small customized batches to high-volume manufacturing, we offer flexible, scalable solutions.

-

Certified Quality

ISO 9001 certification ensures that every process aligns with global quality management standards.

Partner with QANYU

QANYU’s precision machining expertise, combined with rigorous inspection and flexible production capability, makes us a trusted CNC machining manufacturer for companies seeking accuracy and reliability in every component.

Contact us today to learn how our CNC machining and testing capabilities can enhance your product performance and streamline your supply chain.