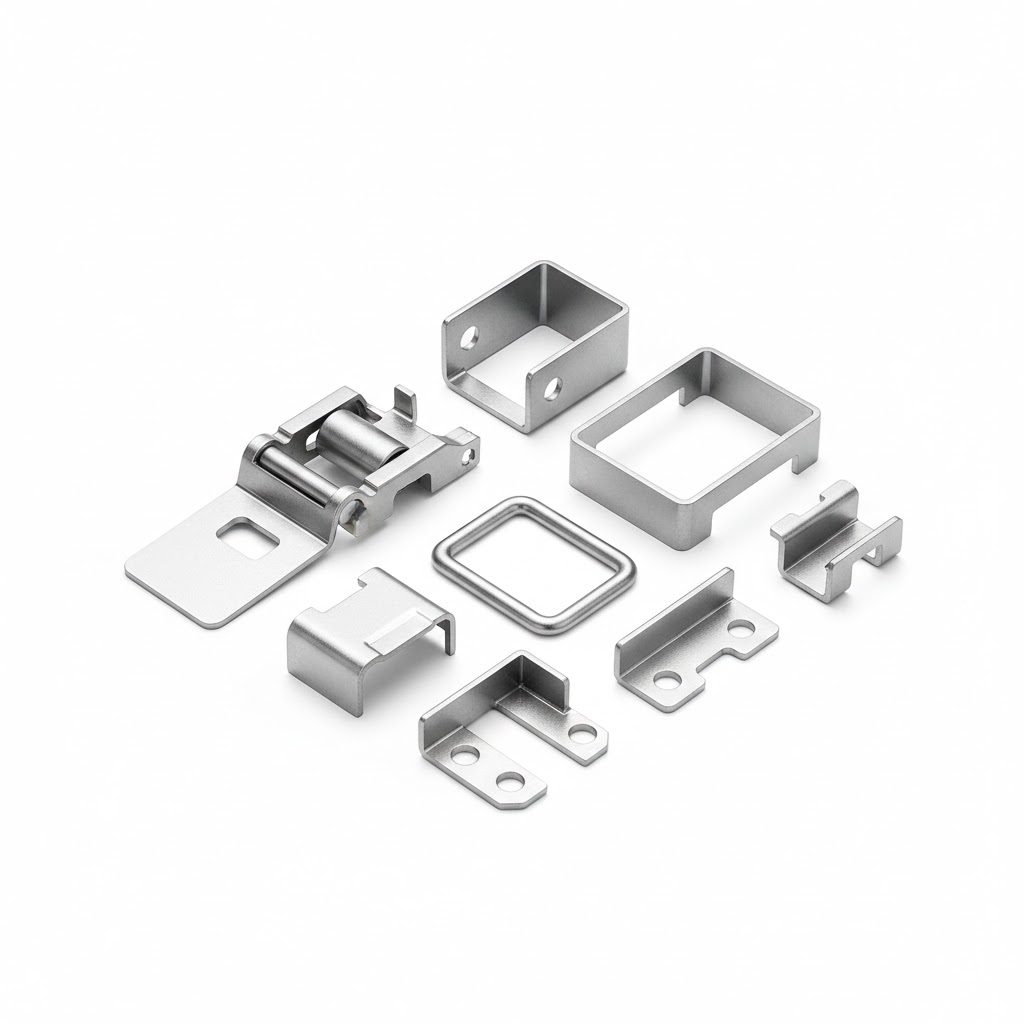

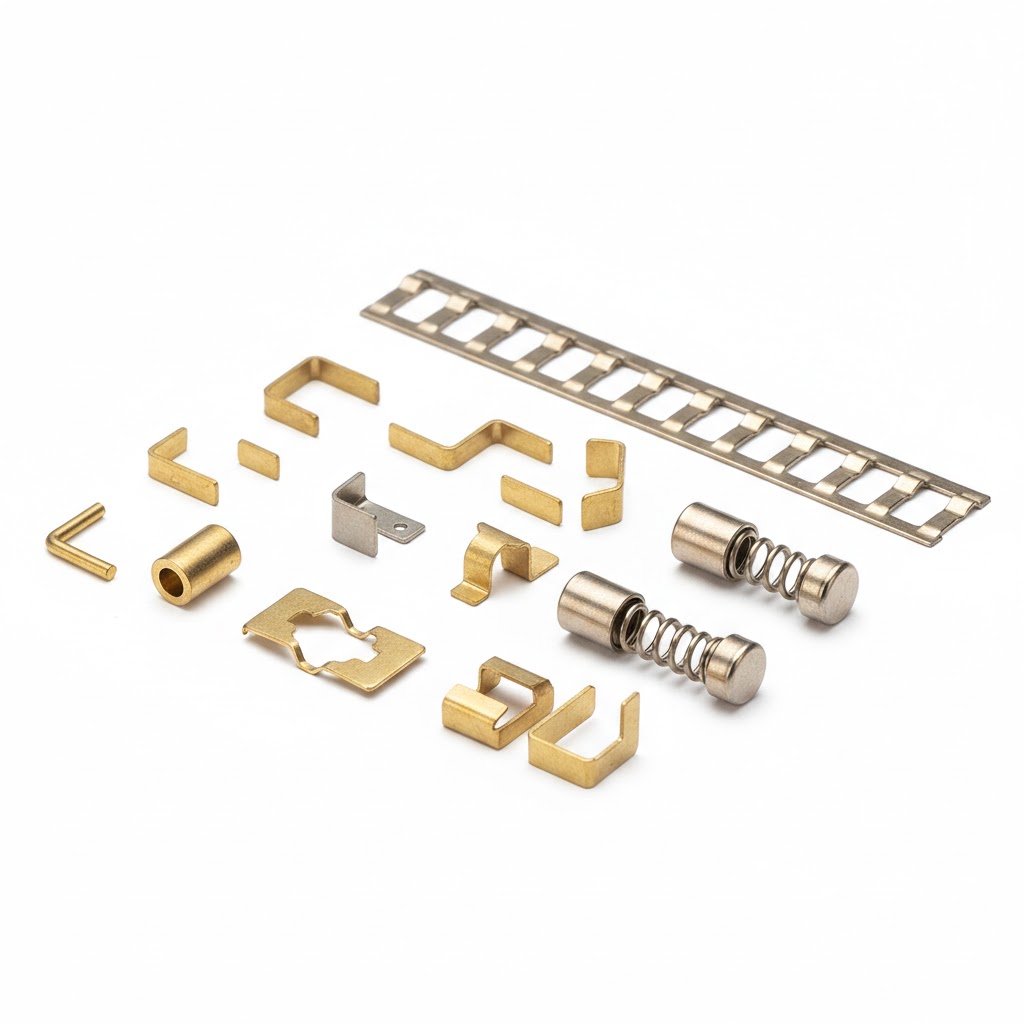

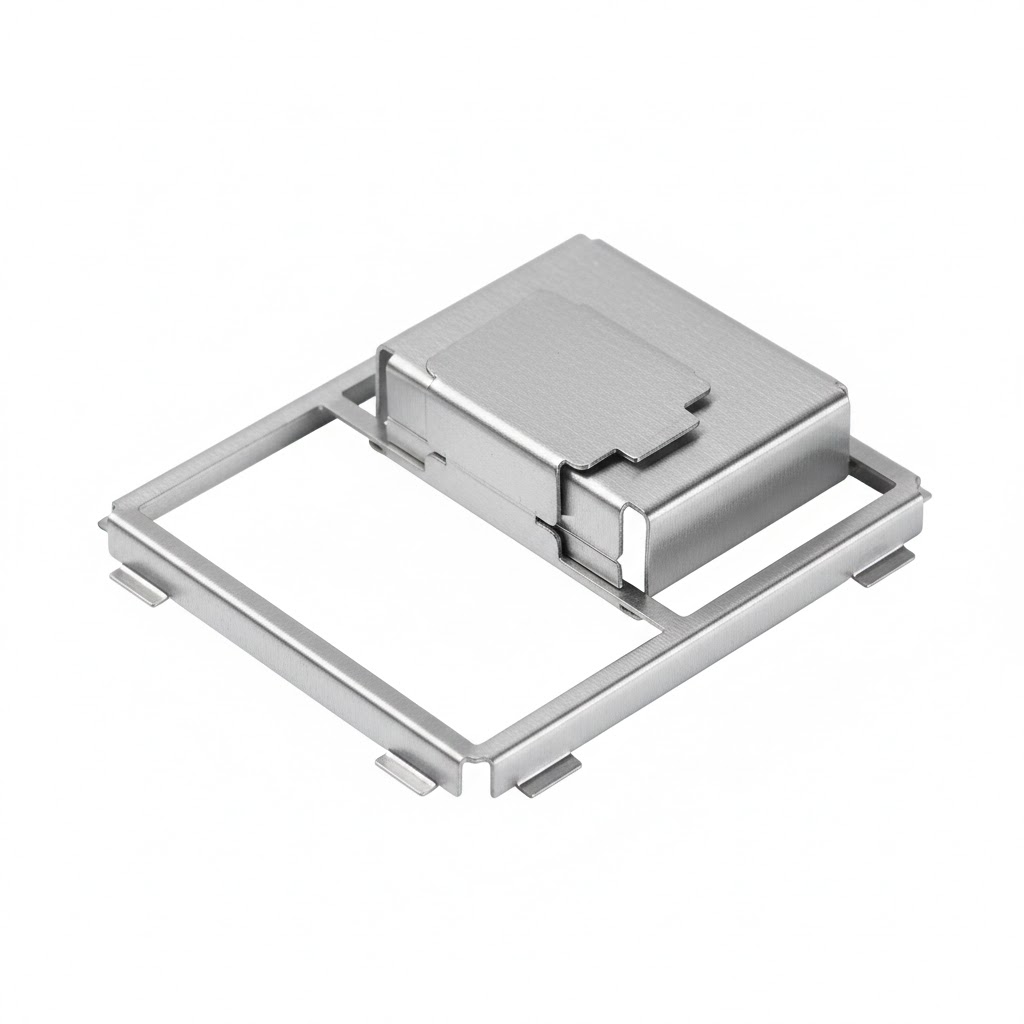

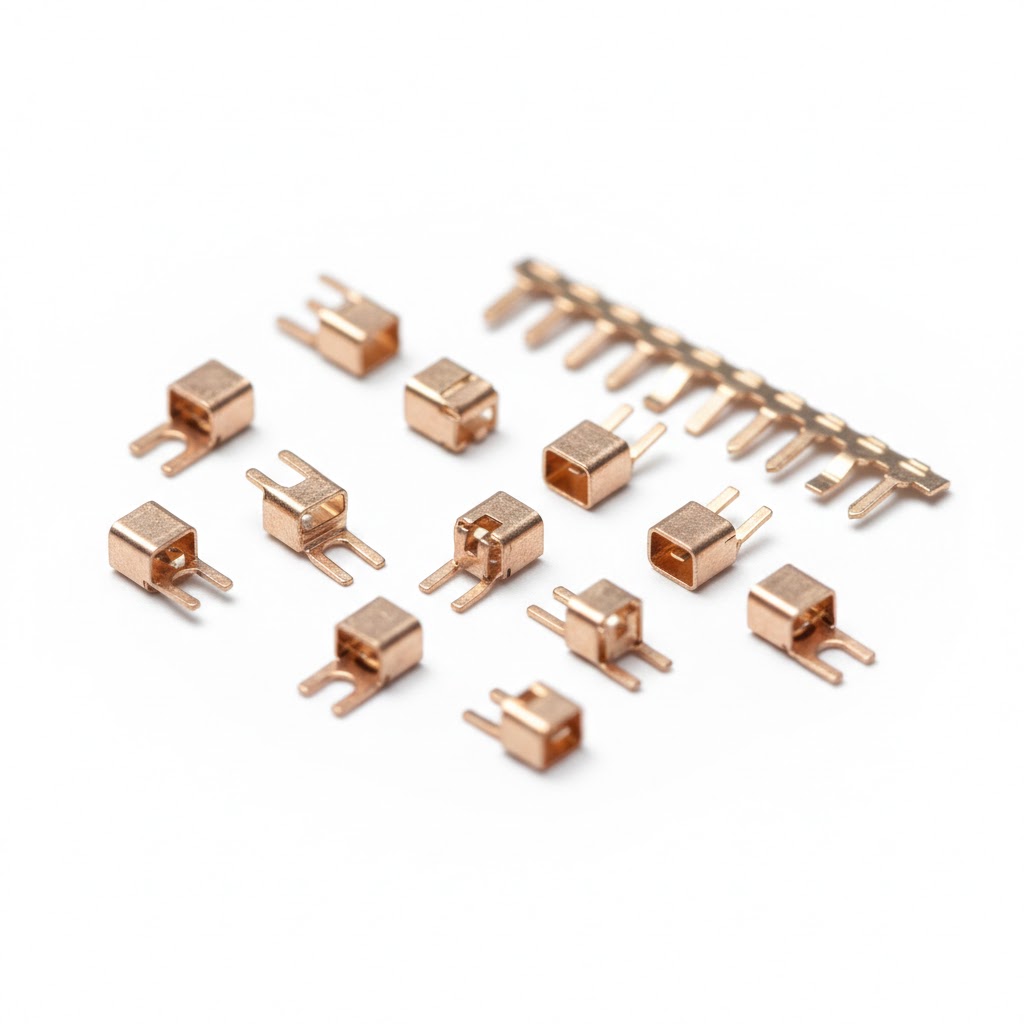

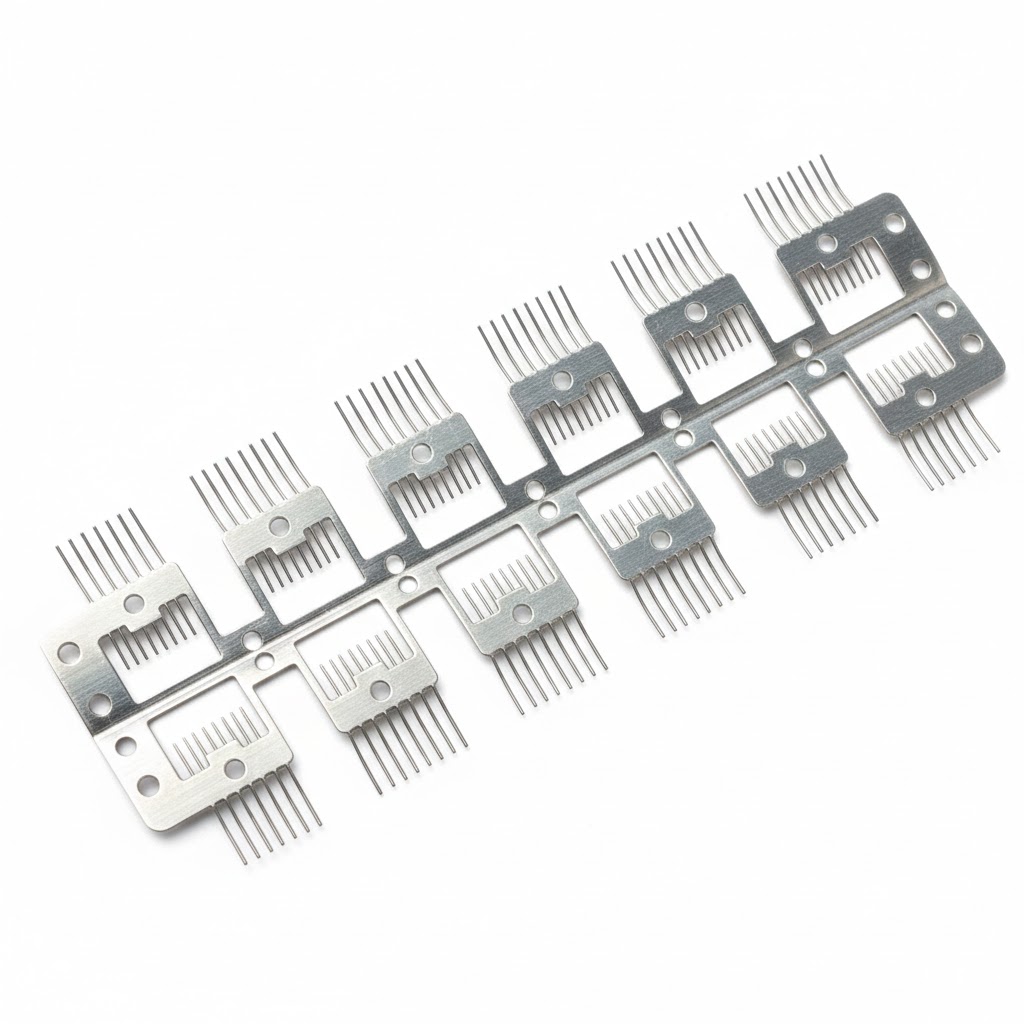

At QANYU, our metal stamping technology transforms raw materials into high precision parts — fast, efficient, and consistent. Using advanced press machines and precision-engineered dies, we shape metal sheets into components that drive industries from automotive to electronics. Stamping is a cold-forming process performed at room temperature. Through cutting, bending, forming, or drawing, the metal is pressed into the desired shape with exceptional accuracy. Each process delivers reliability and repeatability — essential for high-volume production.

• Shearing: Cuts material into exact shapes.

• Bending: Creates angles and curves with precision.

• Forming: Presses metal into defined mold cavities.

• Drawing: Stretches or compresses material for deep shapes.

At QANYU, we use advanced press machines and custom stamping dies to deliver both speed and precision. From small intricate parts to large structural components, our stamping solutions cover diverse applications — including automotive panels, appliance housings, and electronic parts.

1. High Efficiency: Ideal for mass production with minimal material waste.

2. Superior Precision: Tight tolerances and consistent quality every cycle.

3. Design Versatility: Supports complex shapes, thin walls, and detailed geometries.

4. Scalable Solutions: From prototyping to full-scale production.

• Precision Stamping: For high-accuracy parts in electronics and optics.

• Micro Stamping: Ideal for miniature components and delicate materials.

• Stamp Forging: Combines stamping and forging for extra strength and durability.

At QANYU, we don’t just stamp metal. We engineer precision, performance, and production efficiency into every part.